Robot Design, Mobile Integrated Systems Design

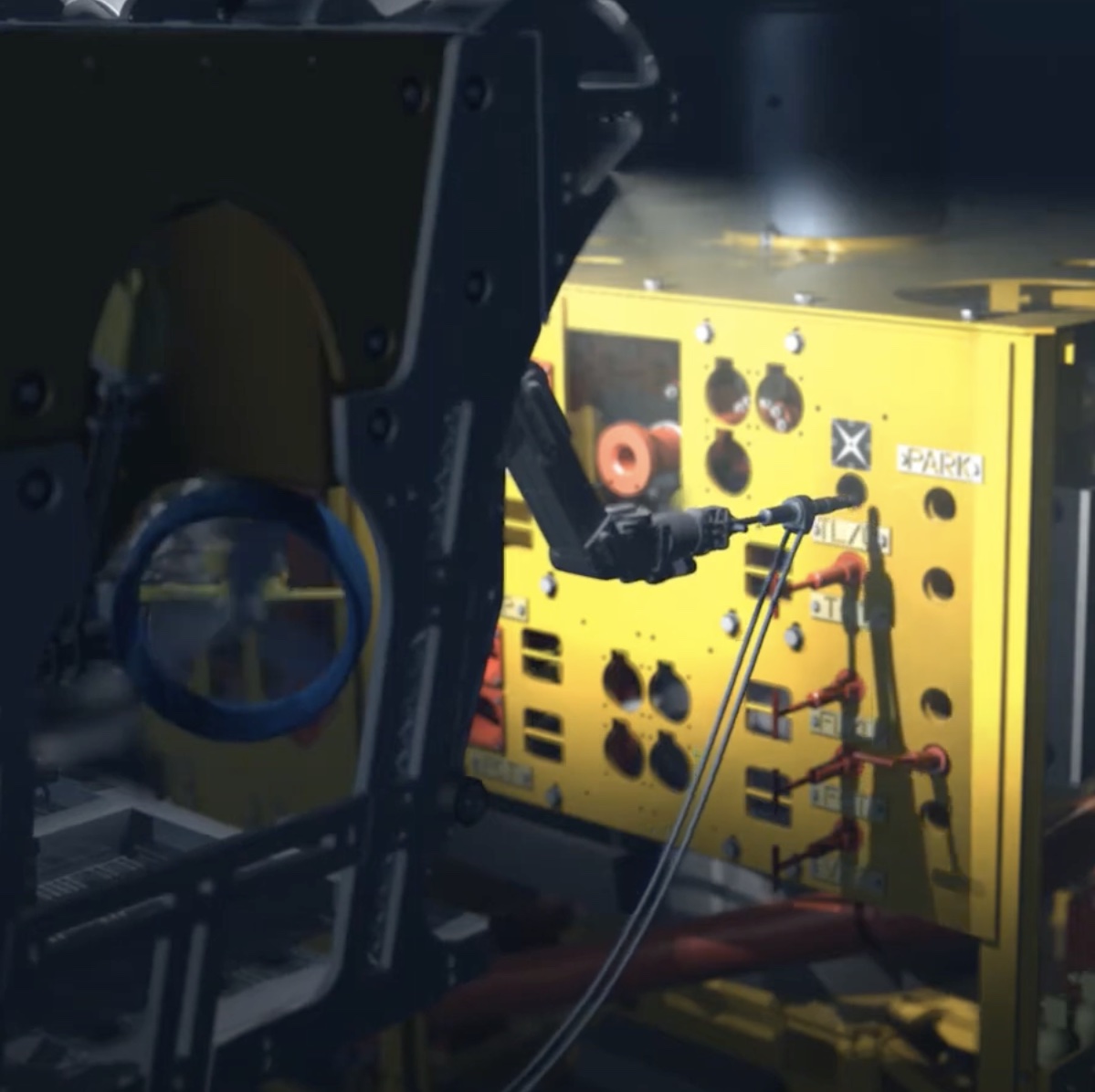

During covid, I had the opportunity to design a robot from scratch at Google X.

In under 2 years, we went from a top level concept to working robots delivered in multiple countries.

As the only electrical engineer on the project, I did everything from electronics concept, component selection, power budgeting,

PCB design, firmware, system integration, setting up contract manufacturing and a test program.

I've also designed robots for space, underwater, defense, aerospace, and industrial applications.